A few weeks ago, we published our first blog in our series about the new DGR System – a system that pairs geolocation accuracy with ag drones and sensors to simplify the data collection process – making it three times more efficient than with today’s standard workflows.

Today, we’re continuing the series with a deep dive into how the DGR System works in the field with some real-world examples and benefits.

Optimizing Ag Research: Multispectral Mapping

When looking at how the DGR System supports researchers in ag, it complements the 6X sensor work to make it even a more optimal solution for researchers in the field. In ag research, precision and accuracy are key to gaining the results needed – which is exactly what the DGR System and the 6X sensor do when paired together.

The 6X sensor offers high-resolution multispectral images with science-grade quality to give deeper detail to researchers – maximizing accuracy and precision for data collection and analysis. Multispectral indices, like NDVI and NDRE, provide insights into crop health and growth stage that aid in powering decisions and research efforts.

Going beyond RGB gives a clearer indication and fast analysis of crop performance to allow for quicker response and the opportunity to optimize results. This type of efficient and detailed imagery can accelerate findings with more detailed data sets to supplement primary research goals.

With the added geolocation accuracy, the DGR System makes location tracking more accurate – meaning each image can easily be paired with a location on the field, all without having to use extensive ground control points in the problem.

As you can imagine, knowing the precise location of each image makes it possible to apply it to reference it back to a plot trial layout. Therefore, allowing us to determine the best photo for each plot – or which picture contains the full view of the plot. Analyzing plot-level multispectral data directly from images, rather than mosaics, allows for higher data quality because the errors introduced during the stitching process are eliminated.

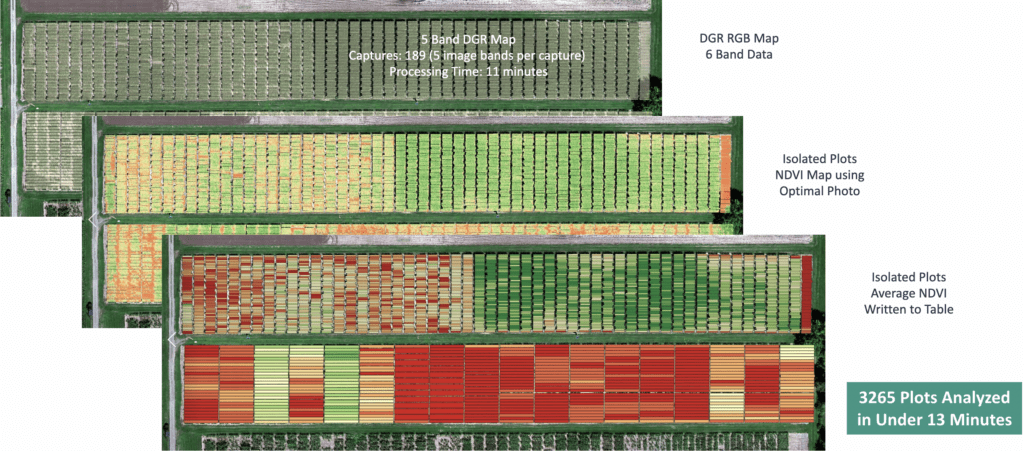

The photo below shows three different examples of individual image/plot analytics captured by using the 6X with the DGR System.

Over 3,000 plots analyzed in under 13 minutes? Talk about freaky fast!

Without the DGR, this would typically take six or seven hours as the images would have to go through stitching to create a map with the high-resolution aerial imagery. Imagine being able to go to the field to capture data, and before leaving the field, have a good indication of performance and where inputs may be necessary?

While efficiency gains may be appealing enough, it’s important to note that DGR System also preserves data integrity – helping to maximize data quality by delivering higher radiometric quality directly from the system.

Less Time, More Accuracy: Optimizing Crop Production with the DGR System

The DGR System’s specialties depend on the paired sensor. In addition to the 6X, the DGR System will integrate with the 65R, our ultra-high-resolution aerial sensor that delivers sharper imagery for the highest precision RGB imagery.

The 65R was built from the ground up for seamless drone integration, helping to accelerate productivity while delivering more precise, accurate aerial data. With a ground sampling distance of 0.3cm at 125 feet, it results in more pixels per image – meaning you can capture more detail in every single image to fuel critical decisions around key inputs or treatment options.

Check out the two maps captured by the 65R below – one showing a stitched orthomosaic, the other from the DGR System and 65R together:

When looking over the two images, visually there are no differences and essentially, they look the exact same. The top image is an orthomosaic map compiled of 239 photos that took a whopping four hours to process. The map processed after a flight with the DGR System and 65R was made with only 60 photos and took only 25 minutes to process.

Beyond saving time for post-processing, using the DGR System paired with the 65R means faster flights. And we know that every minute matters when it comes to seed production. This efficiency assists in making time-sensitive decisions based on high-res imagery, before it is too late. Such as identifying weed locations across an entire field – gaining access to crucial data this fast allows for maximized outcomes.

Complicated Maps? Not a Problem

Traditionally, it has been difficult to capture and stitch scenes where we see outside factors changing the scenery. For example, with the wind changing direction, it can be difficult to build maps around the changes that the wind causes. When a drone makes passes to capture imagery, it’ll look different when the winds changes – and thus, make it challenging to create an orthomosaic map from the images.

The same goes for water and tassels. When waves continuously move, it disrupts the stitching process, making it impossible to complete the map. These changes that are otherwise virtually impossible to capture correctly for the stitching process can now be corrected and built around with the DGR System.

The value that DGR System brings? The DGR System’s parts are designed to deliver absolute location certainty. This eliminates the main sources of error for stitching, and in these situations, means you can actually get the detailed image required to fuel critical decisions.

Whether in ag research, seed production, or have a unique need for a detailed agricultural map, the DGR System finally offers a solution to meet these dynamic needs with precise, accurate data while delivering workflow efficiencies in the process.